In 2026, the construction industry continues to evolve, and so must our approach to using technology. The Potain Tower Crane stands out as a vital tool in modern construction projects. This crane enhances efficiency, safety, and productivity, essential aspects of today's fast-paced building environment.

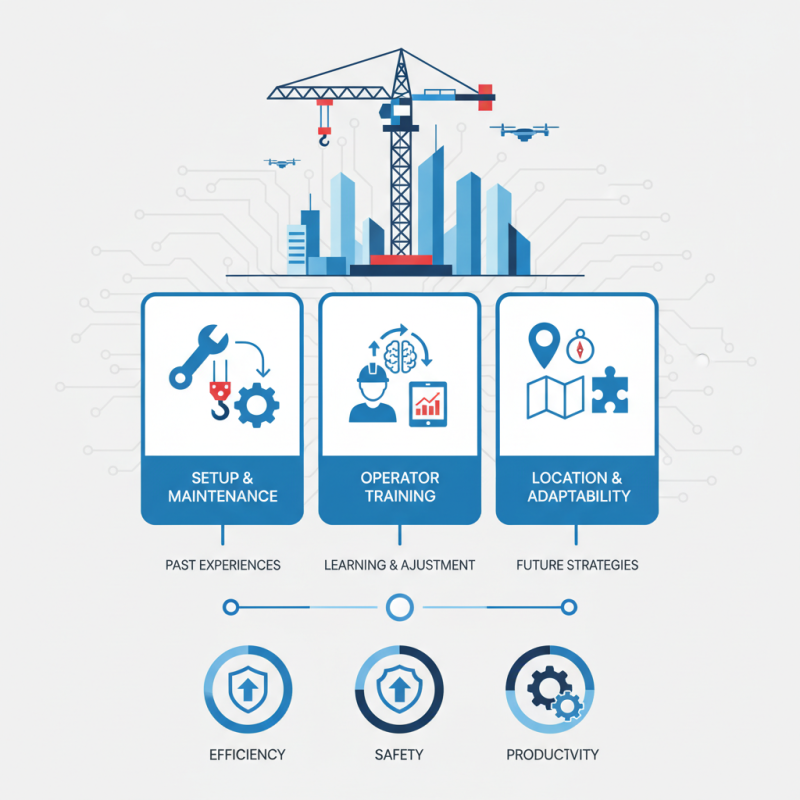

When using the Potain Tower Crane, operators must focus on proper setup and maintenance. A well-maintained crane reduces risks and enhances performance. However, challenges can arise. Not all operators may fully understand the crane's features or limitations. Effective training is crucial for maximizing its potential.

Moreover, the choice of location impacts the Potain Tower Crane's effectiveness. An optimal site maximizes reach and minimizes obstruction. Yet, construction teams must remain adaptable. Unexpected issues can lead to setbacks. Continuous learning and adjustments are key to overcoming these hurdles. By reflecting on past experiences, teams can improve their strategies for using Potain Tower Cranes in 2026.

When considering Potain tower cranes, understanding their specifications is essential for effective operation. These cranes typically reach heights of up to 265 meters. Their lifting capacity can vary, commonly ranging from 1 ton to over 25 tons. The design allows easy transport. However, operators often overlook the importance of load charts.

Load charts provide crucial information distinct to each model. Misinterpretation can lead to unsafe practices. For instance, a common error is underestimating the weight of materials. With 2026’s construction trends emphasizing sustainability, knowing crane capacity ensures efficient resource management. Furthermore, these cranes offer a wide working radius, usually extending from 30 to 75 meters. This range allows flexibility on job sites but can present challenges. Miscalculating distances might lead to safety hazards or project delays.

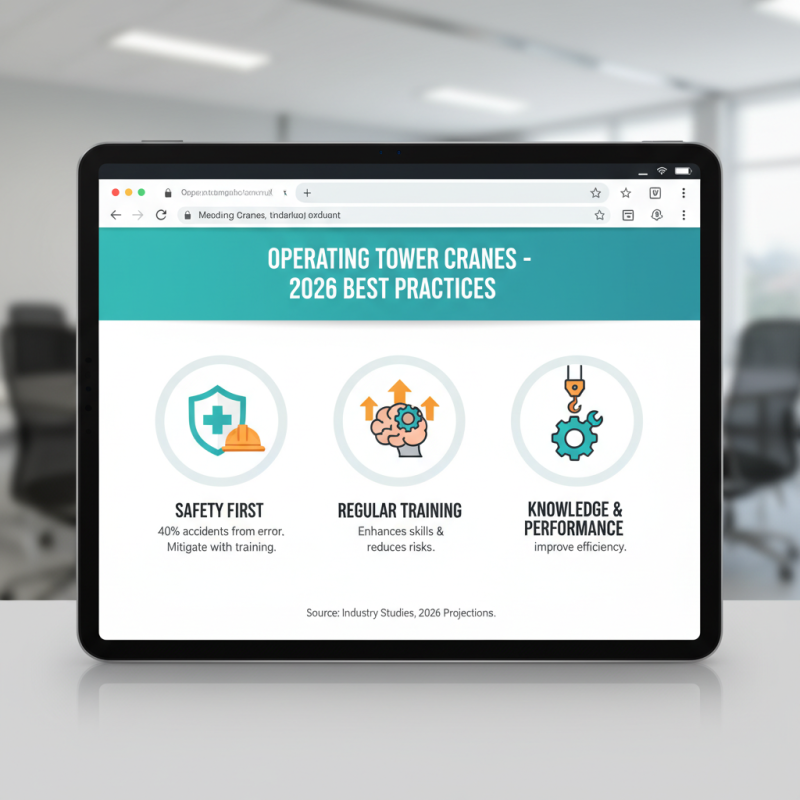

Some features go beyond basic specifications. Advanced control systems enhance precision. However, operators might struggle with complex controls. Training programs can help address this gap. According to recent reports, nearly 40% of crane incidents stem from operator error. Investing in ongoing education is vital. It is not just about having equipment; using it effectively requires knowledge and skill. Understanding these specifications and features can lead to better outcomes on job sites.

| Specification | Description | Advantages | Limitations |

|---|---|---|---|

| Maximum Load Capacity | Up to 10 tons | Suitable for heavy lifting | Requires substantial setup space |

| Working Height | Up to 200 meters | Ideal for high-rise construction | Wind conditions can limit usage |

| Rotation Radius | 360 degrees | Versatile operation in tight spaces | Limited by surrounding structures |

| Power Supply | Electric (requires grid connection) | Environmentally friendly operation | Dependence on electrical infrastructure |

| Control System | Remote and manual control options | Enhanced safety and operational flexibility | Potential for operator error |

Assessing site conditions is fundamental for effective tower crane operation. In 2026, this evaluation will be even more crucial, given the increasing complexities of construction projects. Reports indicate that over 65% of crane accidents stem from improper site assessments. Factors such as ground conditions, terrain type, and proximity to existing structures can dramatically affect crane placement. For example, soft soil may require additional support to stabilize the crane, increasing costs and time.

Wind conditions also demand attention. Data show that strong winds can reduce crane productivity by 25% or more. Understanding local weather patterns is vital. It’s essential to assess these conditions regularly. Moreover, observing the site for potential hazards—like overhead power lines—is key. Such oversights can lead to costly delays and safety incidents.

When choosing a crane placement, consider not just current conditions, but future project phases. An optimal location today may become problematic tomorrow. Site evaluations should be continuous, adjusting for unforeseen changes. Often, teams realize too late that initial assessments were flawed. This necessitates a culture of vigilance and flexibility on site.

Effective operation of tower cranes in 2026 requires adherence to best practices. Safety is paramount, with studies indicating that approximately 40% of crane accidents are attributed to operator error. Regular training sessions can help mitigate these risks. Ensuring operators are well-versed in the crane's features can improve performance.

Communication remains a vital aspect of crane operation. Using designated hand signals can reduce confusion on-site. A recent survey found that projects utilizing clear communication protocols saw a 30% increase in efficiency. Operators should also conduct routine checks. Not all equipment performs flawlessly. Skipping inspections can lead to costly delays and potential hazards.

Load management is another crucial element. Understanding load capacities is essential to avoid accidents. The failure rate associated with overloaded cranes is alarming, with some studies reporting up to a 20% increase in incidents. Maintaining a log of loads lifted helps track performance and identify any trends in operation. Continuous reflection on these practices can lead to a safer and more efficient work environment.

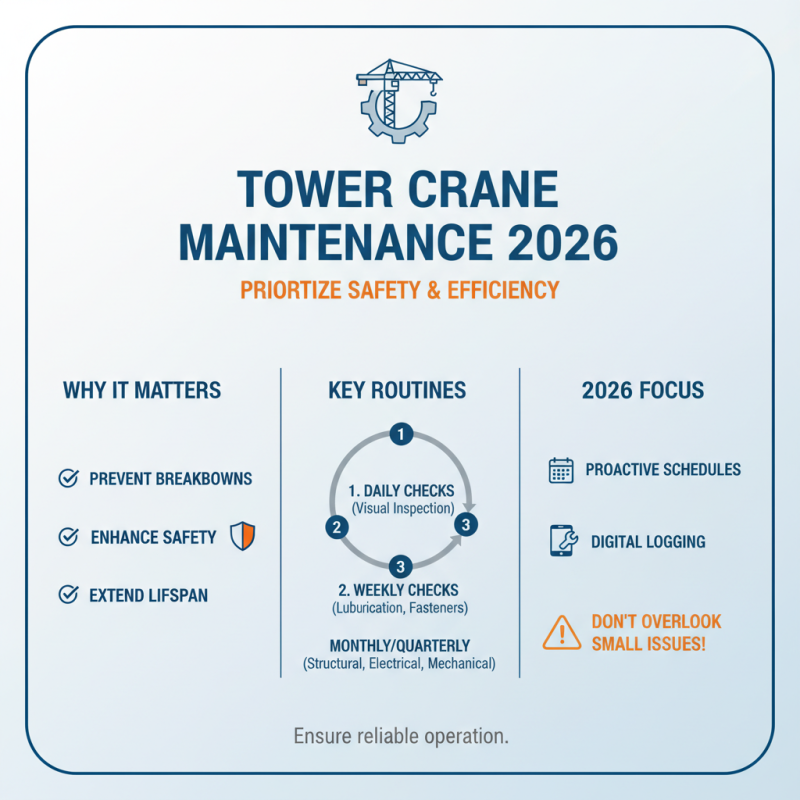

Regular maintenance and inspection routines are crucial for the effective operation of tower cranes. In 2026, operators must prioritize these practices to ensure safety and efficiency. A well-planned maintenance schedule can prevent unexpected breakdowns. This includes checking all mechanical components regularly. Small issues can escalate if they are overlooked.

Inspection routines should be thorough. Operators should focus on structural integrity, brakes, and electrical systems. Keeping a detailed log of inspections is essential. It allows teams to track the crane's performance over time. If something seems off, it must be addressed immediately. Training staff on spotting these issues can lead to better awareness and quicker responses.

Frequent use can wear down key parts. It’s important to maintain a checklist for inspections. However, human error can happen. Missing a detail could lead to unsafe conditions. Reflecting on past incidents can guide better practices. Continual learning and adaptation are vital for the safe operation of tower cranes.

In 2026, leveraging technology for Potain tower crane operation will fundamentally reshape the construction landscape. Advanced telemetry systems are crucial. They provide real-time data about load weights, crane angles, and wind conditions. According to the International Construction Market Report, 65% of construction companies are adopting IoT solutions for increased safety. This is vital for reducing accidents and ensuring workers’ safety on-site.

Automation also plays a significant role in crane efficiency. Robots and AI can optimize crane positioning. Data from a recent industry study shows that automated systems can reduce operation time by up to 30%. Nonetheless, it’s essential to recognize the challenges these technologies bring. Operators may struggle with the new systems. Training and adjusting to these technologies is a learning curve that cannot be overlooked.

Technical malfunctions can occur, leading to delays. Moreover, integrating these high-tech solutions with existing infrastructure may face resistance. Clear communication and strategic planning will be essential to overcome these hurdles in 2026. Only through a well-thought-out approach can the full potential of technology be realized, maximizing efficiency while ensuring safety and productivity on site.

This chart illustrates the projected operational efficiency of Potain tower cranes over the months of 2026. The data reflects an upward trend in efficiency, leveraging advanced technology and operational strategies. Effective management and automation are key factors contributing to this increase.