As the construction industry evolves, so does the technology that powers it. Among the leaders in innovation is Liebherr Tower Crane, renowned for its commitment to excellence and cutting-edge advancements. In 2025, a new wave of innovations is set to redefine the capabilities and efficiencies of these towering giants on construction sites around the globe. This article explores the top 10 Liebherr Tower Crane innovations that are poised to make a significant impact in the industry.

From enhanced automation features to advanced data analytics, Liebherr Tower Crane innovations are not just about lifting heavy loads; they are about lifting the standards of safety, efficiency, and performance. Each of these innovations aims to streamline the construction process, reduce operational costs, and address the growing demand for sustainable building practices. Join us as we delve into the latest trends and tips that will set the benchmark for the future of Liebherr Tower Cranes, ensuring that they remain at the forefront of construction technology.

As we look toward 2025, the tower crane industry is poised for revolutionary developments that reflect the ever-evolving demands of construction and infrastructure projects. According to recent reports, the tower crane market is projected to reach USD 36,971.1 million by 2035, with a steady growth rate of 4.8% CAGR. This growth is spurred by innovations in technology that enhance efficiency, safety, and automation in lifting solutions.

At Bauma 2025, expect to see groundbreaking exhibits that showcase these advancements. With over 70 future-focused displays, attendees will have the opportunity to experience first-hand the latest technological innovations shaping the industry. Tower cranes are becoming smarter, integrating features such as IoT capabilities and advanced load monitoring systems, which not only improve operational safety but also enhance productivity on construction sites.

Tip: When considering the implementation of new tower crane technologies, assess the specific needs of your projects and how these innovations can lead to long-term savings and efficiency gains.

These technological advancements are paving the way for the next generation of tower cranes. By investing in innovative solutions, construction companies can not only improve their operational capabilities but also align with sustainable practices that are increasingly valued in today’s market.

Tip: Keep an eye on industry reports and exhibitions to stay informed about the latest advancements and best practices to ensure your business remains competitive in this rapidly evolving landscape.

The construction industry is increasingly prioritizing sustainable practices, and Liebherr cranes are at the forefront of this evolution. With advancements in technology, Liebherr is committed to integrating sustainable features that enhance efficiency and reduce environmental impact. According to a report by the International Energy Agency, buildings account for nearly 40% of global energy use and related CO2 emissions. By innovating timber cranes and utilizing smarter, more energy-efficient systems, Liebherr aims to significantly reduce the carbon footprint associated with construction activities.

One promising development is the adoption of electric and hybrid power systems, which can lead to reductions in fuel consumption by up to 30% compared to traditional diesel-powered cranes. These new models not only provide superior performance but also align with the global push for greener building practices. Additionally, enhancements in load management systems allow for optimized energy use during lifting processes, resulting in further efficiency gains. According to industry analysts, the integration of such sustainable features is projected to drive a 25% increase in operational efficiency for Liebherr cranes by 2025, showcasing the company's commitment to a more sustainable future in construction.

The construction industry is continuously evolving, and Liebherr tower cranes are at the forefront of innovation, particularly in safety enhancements. With an alarming rate of construction site accidents—over 20% of all workplace fatalities occurring in this sector—the focus on robust safety measures is more crucial than ever. Liebherr is addressing these challenges by integrating advanced technology into their tower cranes, ensuring the well-being of workers while maximizing operational efficiency.

One significant advancement is the incorporation of real-time monitoring systems that use sensors to detect anomalies or unsafe conditions. These systems can alert operators immediately, reducing response times to potential hazards. According to a report from the Occupational Safety and Health Administration (OSHA), implementing such proactive safety measures can decrease accident rates by up to 30%. Emphasizing these innovations, Liebherr aims not only to enhance safety but also to fulfill regulatory requirements, ensuring compliance and trust on construction sites.

**Tips:** To maximize crane safety on your site, regularly inspect equipment and conduct training sessions for all operators. Investing in a comprehensive safety management system is also a smart move to help keep track of compliance and safety protocols. Remember, a focus on safety boosts efficiency and worker morale, ultimately benefiting the entire project.

| Innovation | Description | Safety Feature | Expected Impact |

|---|---|---|---|

| Smart Load Monitoring | Technology that tracks and displays real-time load weights. | Prevents overload conditions. | Reduces accidents and improves operational efficiency. |

| Enhanced Wind Speed Monitoring | Advanced sensors to gauge wind conditions and adjust operations. | Stops operations in high wind scenarios. | Increases safety during adverse weather conditions. |

| Automatic Shutoff Systems | Immediate shutdown of operations when safety limits are reached. | Prevents potential accidents. | Enhances site operator confidence. |

| Operator Augmented Reality (AR) Systems | Integration of AR to assist crane operators with enhanced views. | Improves situational awareness. | Accelerates decision-making and reduces errors. |

| Biometric Operator Authentication | Facial recognition or fingerprint scanning for crane access. | Ensures only authorized personnel operate equipment. | Improves site security and accountability. |

| Remote Monitoring Systems | Allows for remote supervision of crane operations. | Maintains safety oversight from a distance. | Better emergency response and monitoring. |

| Advanced Stability Features | Focus on ensuring crane stability through technology. | Reduces risk of tipping. | Increases reliability on construction sites. |

| Improved Emergency Response Systems | Integrated systems to quickly address emergencies. | Ensures swift action during incidents. | Minimizes injury and damage during accidents. |

| User-Friendly Control Interfaces | Intuitive controls to enhance operator experience. | Reduces operator stress and fatigue. | Improves overall site safety and efficiency. |

| Environmental Adaptation Features | Design aspects that allow cranes to function in various climates. | Maintains functionality during extreme weather conditions. | Extends operational timeframes. |

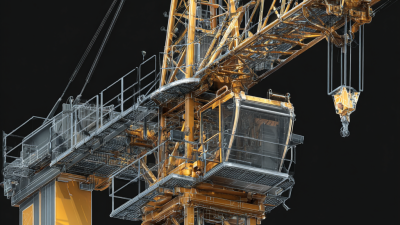

In recent years, Liebherr has been at the forefront of integrating digital technology into tower cranes, setting the standard for innovation in the construction industry. The 2025 lineup highlights smart integration features that enhance operational efficiency and safety. With advancements such as real-time data monitoring and IoT connectivity, operators can now access vital information directly from their devices, allowing for streamlined project management and quicker decision-making. These technologies ensure that potential issues are identified and addressed before they escalate, significantly reducing downtime.

Moreover, Liebherr’s commitment to user-centric design is reflected in the development of intuitive software interfaces. This evolution includes advanced analytics that support predictive maintenance, helping businesses decrease unexpected equipment failures and extend the lifespan of their cranes. By harnessing digital twins and machine learning algorithms, Liebherr is enabling cranes to adapt to changing conditions on-site, improving not just performance but also contributing to sustainable practices within the industry. As 2025 approaches, these innovations promise to redefine how construction projects are executed, making them smarter and more efficient than ever before.

Liebherr has consistently pushed the boundaries of engineering excellence, and its 2025 tower crane innovations are no exception. The focus on user-centric design enhancements is evident in the latest models, which prioritize operator comfort and efficiency. These cranes come equipped with intuitive control systems that allow operators to manage complex tasks with precision. By ergonomically redesigning the operator cabins, Liebherr ensures that visibility is maximized, reducing blind spots and enhancing safety on job sites.

In addition to improved visibility, the new Liebherr tower cranes feature advanced digital interfaces that streamline operations. Operators can easily access real-time data on crane performance and site conditions, allowing for smarter decision-making amidst changing environments. The integration of IoT technology not only enhances communication between cranes and operators but also allows for predictive maintenance, minimizing downtime and increasing productivity. These user-centric innovations are set to redefine the standards of construction equipment in 2025, making Liebherr a leader in the field.