Mobile Tower Cranes have gained immense popularity in the construction industry. These cranes combine the benefits of both mobile and tower cranes, offering flexibility and strength. John Smith, an expert in the industry, states, “A Mobile Tower Crane can revolutionize the way projects are executed.”

These cranes are designed for a multitude of terrains. They adapt quickly, which is crucial for busy construction sites. Their compact size allows access to areas where traditional cranes may struggle. However, some projects still overlook their potential. Many builders remain hesitant to adopt new technology, missing out on these benefits.

Cost efficiency and operational ease are vital advantages of Mobile Tower Cranes. They minimize labor and equipment costs. Yet, not every operator is familiar with their features. Training needs vary, and companies must invest time to maximize their use. There’s a balance between embracing innovation and ensuring practical application in everyday tasks.

A mobile tower crane is a versatile construction tool. It combines the features of both mobile and tower cranes. This hybrid structure can be transported easily from one site to another. Its flexibility makes it ideal for various types of projects, from small buildings to large infrastructure developments.

These cranes are particularly useful in urban areas. Their compact design allows them to access tight spaces where traditional cranes cannot fit. This is crucial when working in crowded environments. Many construction teams appreciate how quickly a mobile tower crane can be set up. This efficiency can significantly reduce project timelines.

However, not all aspects are perfect. Some operators struggle with the setup process, particularly under tight schedules. This can lead to delays, causing frustration. Additionally, the reach and lifting capacity may vary significantly between models. Choosing the right crane for a project requires careful consideration and planning. Understanding these nuances is key to maximizing the benefits of mobile tower cranes.

A mobile tower crane is a versatile construction piece. Its essential components are critical for efficient operation. At the core is the tower itself. It provides stability and height, reaching up to 200 feet or more in some configurations. The base, often a sturdy frame, supports the entire structure. It helps distribute weight evenly, minimizing risks during operation.

The jib is another key component. It extends out from the tower, enabling the crane to lift loads. Depending on its design, a jib can reach considerable lengths. Reports indicate that mobile tower cranes can handle loads of up to 20 tons, making them effective for various projects. The winch system is crucial too. It powers the lifting mechanism, ensuring safety and reliability.

However, not everything about mobile tower cranes is perfect. Setup can be time-consuming and requires skilled operators. Maintenance is also vital; neglecting it can lead to issues. Industry studies show that improper maintenance increases the risk of accidents. Therefore, while mobile tower cranes are efficient, they demand careful attention to their components and operations.

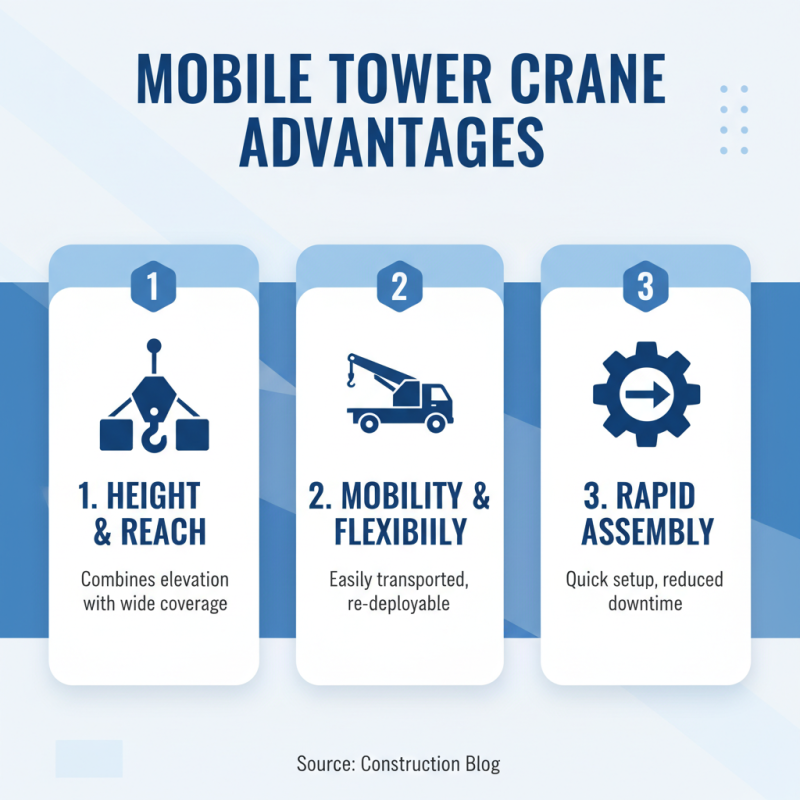

Mobile tower cranes offer several key advantages that make them ideal for various construction projects. Their ability to combine height with mobility is significant. These cranes can be easily transported to different sites, providing flexibility where it’s needed most. They can be assembled quickly, reducing downtime and ensuring workers can start their tasks promptly.

One of the main benefits of mobile tower cranes is their ability to operate in confined spaces. Many urban environments have limited access, making traditional cranes impractical. Mobile tower cranes are designed to fit in tight spots without sacrificing efficiency. However, it is essential to note that accurate site assessment is necessary for optimal performance. Users must constantly evaluate ground conditions and load weights.

Another advantage is their lifting capacity. Mobile tower cranes can handle heavy loads, making them versatile for various applications. Yet, operators must remain vigilant about safety protocols. Neglecting these can lead to accidents or damage. Regular training and proper maintenance are crucial to ensuring their functionality. Each project presents its challenges, and reflections on past experiences can guide improvements.

Mobile tower cranes are versatile machines in modern construction. Their design allows for quick setup and breakdown. They are often used in urban areas due to their compact size. This adaptability is crucial in dense settings where space is limited.

In building high-rise structures, mobile tower cranes provide efficiency. They can lift heavy materials, like steel and concrete, with ease. This capability reduces the time required for construction. Workers can focus more on assembly rather than transporting materials.

Tips: When using a mobile tower crane, ensure proper operator training. Knowledge of load limits and safety protocols is vital. Always check for nearby power lines to avoid accidents. These simple precautions can save time and lives. Additionally, consider the crane's height and reach before positioning it. Planning ahead leads to smoother operations.

Operating a mobile tower crane involves specific safety considerations that cannot be overlooked. The operator must conduct a thorough pre-operation inspection. This includes checking the crane's stability, ensuring all safety devices are functional, and looking for signs of wear. Visibility is crucial. Surrounding conditions should be assessed to avoid obstructions and hazards.

Training for operators is not just recommended; it is essential. Proper training helps operators respond to emergencies effectively. They should understand load limits, communication signals, and equipment functions. Furthermore, the crew must work closely together. Effective communication prevents accidents and enhances safety.

Weather conditions play a significant role too. Wind can drastically affect crane operations. Operators should constantly monitor weather updates. If conditions become unfavorable, halting operations may be necessary. Reflecting on past incidents can also improve safety protocols. Learning from mistakes helps prevent future accidents. Safety remains a shared responsibility among all personnel on site.