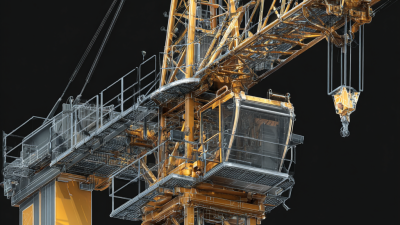

In the ever-evolving landscape of construction equipment, the importance of optimizing the parts of tower crane cannot be overstated. As these towering giants become integral to modern building projects, understanding and comparing the various components that comprise them is essential for enhancing efficiency, safety, and performance. This blog will delve into the innovative solutions for the essential components of tower cranes, exploring how advances in technology, materials, and design are revolutionizing their functionality.

By examining different types of parts of tower cranes, we will uncover the advantages and challenges associated with each, providing valuable insights for industry professionals and decision-makers seeking to implement best practices in their construction processes. Whether you're a contractor, engineer, or enthusiast, this comprehensive comparison will serve as a vital resource for understanding the fundamental elements that drive the success of tower cranes in today's dynamic construction environment.

In the ever-evolving landscape of construction, tower cranes are pivotal in enhancing productivity and efficiency on job sites. The quest for innovative technologies has led to significant advancements in increasing the load capacity of these essential machines. One such breakthrough is the integration of advanced materials like carbon fiber and high-strength steel, which not only reduces the weight of the components but also substantially enhances their strength and durability. This allows cranes to lift heavier loads without compromising stability, transforming the boundaries of what is feasible on construction sites.

Moreover, automation and smart technology play a crucial role in optimizing tower crane performance. The implementation of real-time monitoring systems equipped with sensors and analytics provides operators with critical data, allowing them to make prompt adjustments to lifting operations. Additionally, enhancements in hydraulic systems have improved the efficiency of load handling, enabling cranes to manage heavier weights more smoothly and safely. As these innovative technologies continue to evolve, tower cranes will undoubtedly become even more integral to modern construction, allowing for the successful completion of larger and more complex projects.

The integration of IoT technology in monitoring tower crane performance and safety represents a significant advancement in construction efficiency and risk management. Traditionally, tower cranes have relied heavily on on-site operators to manage daily operations; however, with IoT, real-time data collection and analytics now allow for proactive management of crane activities. A report by the International Society for Automation (ISA) highlights that improved monitoring systems can reduce hazards by up to 30%, making construction sites much safer for workers.

Moreover, the ability to assess carbon emissions using an Integrated BIM-IoT platform during the construction process offers substantial benefits. Recent studies indicate that construction accounts for nearly 39% of global carbon emissions, and by utilizing IoT for real-time tracking, companies can implement more sustainable practices. This technology enables the optimization of multiple-crane service schedules, enhancing transportation efficiency while ensuring operational safety. By adopting these innovative solutions, the construction industry can move towards more environmentally conscious and safer operational standards.

In recent years, the construction industry has made significant strides towards sustainability, particularly in the realm of tower crane manufacturing. The use of sustainable materials not only minimizes the environmental impact but also enhances the overall efficiency of crane operations. For instance, integrating recycled metals and eco-friendly composites can significantly reduce carbon emissions during production. This shift towards greener practices reflects an industry-wide commitment to environmental responsibility.

One way to implement sustainable materials is by opting for recycled steel in the crane structure. Not only does this practice conserve natural resources, but it also reduces energy consumption during the manufacturing process. Additionally, manufacturers can explore bio-based composites for non-structural components, which offer a lower environmental footprint while maintaining structural integrity.

Tips for companies looking to reduce their environmental impact include sourcing materials locally to decrease transportation emissions and collaborating with suppliers who prioritize sustainable practices. Additionally, adopting a lifecycle assessment approach can help manufacturers identify areas for improvement in their production processes, ensuring that sustainability remains at the forefront of their operations. Embracing these innovative solutions will pave the way for a more sustainable future in tower crane manufacturing.

In the realm of construction, tower cranes stand as pivotal machines, and their design is crucial for performance and safety. Advanced design methods for enhancing stability have become increasingly important, as they address the challenges posed by height, load, and wind. Implementing finite element analysis allows engineers to simulate various conditions and identify potential weaknesses in the crane's structure. This proactive approach ensures that cranes can withstand dynamic stresses during operation, leading to safer construction environments.

Tip: Regularly reviewing design parameters and materials used in the construction of tower cranes can lead to significant improvements in efficiency. Lightweight yet durable materials can reduce the overall weight of the crane without compromising strength, enabling better fuel efficiency and reducing operational costs.

Furthermore, incorporating smart technology into crane design enhances not only efficiency but also operational monitoring. Sensors can provide real-time data on load conditions and environmental factors, empowering operators to make informed decisions. This integration of technology not only prevents accidents but also optimizes performance through data-driven insights.

Tip: Encourage continuous training for operators on new technologies and safety protocols to maximize the advantages of smart cranes. This investment in human capital is essential for maintaining safety standards and operational excellence.

| Component | Innovative Design Method | Stability Improvement (%) | Efficiency Gain (%) | Safety Features Implemented |

|---|---|---|---|---|

| Tower Structure | Dynamic Load Adjustments | 15% | 10% | Anti-Tip Sensors |

| Lifting Mechanism | Automated Load Monitoring | 20% | 15% | Load Stability Alerts |

| Rotational Joint | Composite Material Use | 25% | 5% | Enhanced Lubrication Seals |

| Control Systems | AI-Based Load Distribution | 30% | 20% | Smart Collision Detection |

| Base Foundation | Geotechnical Analysis Algorithms | 18% | 12% | Seismic Resilience Design |

In the rapidly evolving construction industry, the integration of automation and artificial intelligence (AI) within tower crane components is set to revolutionize operational efficiency. According to a recent report by Markets and Markets, the construction automation market is projected to reach $238.3 billion by 2025, with a significant portion attributed to advancements in construction equipment, including tower cranes. This trend is driven by the need for greater precision and safety on job sites, where automated systems can minimize human error and optimize lifting operations.

Moreover, as cities continue to grow and the demand for high-rise buildings escalates, the role of smart cranes becomes increasingly pivotal. A study conducted by Dodge Data & Analytics highlights that approximately 55% of construction firms are expected to adopt smart technologies in their crane operations by 2024. Features such as real-time monitoring, predictive maintenance, and remote operation not only enhance productivity but also significantly reduce downtime. By embracing these innovative solutions, the tower crane sector stands to enhance its capabilities, making construction processes more sustainable and efficient in the face of rising challenges.