In the realm of construction and heavy lifting, proper tower crane functionality is paramount for ensuring efficiency and safety on site. As industry expert John Smith, a renowned civil engineer with over 20 years of experience in crane operations, aptly states, "The performance of a tower crane hinges on the quality and condition of its parts; neglecting them can lead to costly downtimes and safety hazards." This highlights the critical importance of understanding the essential tower crane parts that contribute to optimal performance.

Every component, from the hoist and jib to the counterweights and brakes, plays a vital role in the crane's ability to operate smoothly and effectively. In this article, we will explore the top 10 essential tower crane parts that every construction professional should be familiar with. By identifying and maintaining these key components, operators can enhance their crane's performance, minimize risks, and ultimately ensure a more productive work environment. Understanding the intricacies of tower crane parts is not just beneficial—it is essential for success in the competitive construction landscape.

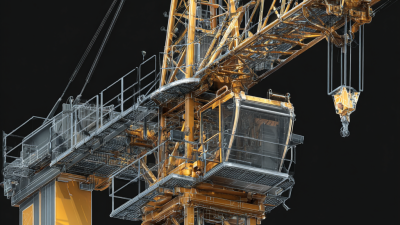

When it comes to tower cranes, understanding their key components is crucial for ensuring optimal performance on construction sites. The primary elements of a tower crane include the tower structure, the jib, the hook, the operator's cab, and the counterweights. According to a report by the International Journal of Engineering Research and Applications, the structure of the tower must be robust, consisting of high-strength steel that can withstand significant loads and environmental conditions.

The jib, which extends horizontally, is another vital component; its design and length directly impact the crane's lifting capacity and reach. Effective lifting operations also hinge on the hook’s design—a critical part that often incorporates advanced materials for durability. A study published in the International Journal of Advanced Engineering Technology highlights that cranes with optimized hook designs can enhance load management and reduce operational risks, improving overall efficiency by up to 20%. Moreover, the counterweights play an essential role in maintaining stability, ensuring that the crane operates safely under various load conditions. Understanding these components not only helps in the selection of the right tower crane but also in maintaining it for peak performance over its lifespan.

The safety and efficiency of tower cranes largely depend on the quality and condition of their wire ropes. These components play a crucial role in load management and ensuring safe lifting operations. In the construction industry, adhering to industry standards regarding wire ropes is paramount to minimize risks. A recent incident highlighted the importance of learning from past mistakes; when a technician passed away due to improper equipment handling, it underscored how essential it is to implement best practices for wire rope usage.

**Tips:** Regularly inspect wire ropes for signs of wear and tear, such as fraying or corrosion. Ensure that all operators are trained on handling and rigging loads correctly. Investing in quality training programs can equip them with essential skills, enhancing both safety and operational efficiency.

Operators should be vigilant and never stand under suspended loads while cranes are in use. The safety notice issued by the US Coast Guard emphasizes this critical point, reminding professionals to be aware of their surroundings and implement safety measures on-site. By prioritizing safety standards and promoting a culture of awareness, companies can significantly reduce accidents and ensure optimal performance of tower cranes.

| Part | Description | Material | Safety Standard | Inspection Interval (months) |

|---|---|---|---|---|

| Wire Rope | High-strength steel rope used for lifting | Steel | EN 13414-1 | 6 |

| Hook | Used to connect loads to the wire rope | Alloy Steel | BS 8110 | 12 |

| Slewing Ring | Allows the crane to rotate | Steel | ISO 9001 | 24 |

| Counterweight | Balances the load being lifted | Concrete / Steel | EN 13000 | 12 |

| Gearbox | Transmits power to the crane's movements | Metal | ISO 9001 | 6 |

| Control System | Manages all crane operations | Electronics | IEC 60204 | 3 |

| Clamps | Secures the wire rope to prevent slipping | Steel | ISO 9001 | 12 |

| Safety Latch | Prevents accidental uncoupling | Steel | EN 818-1 | 6 |

| Limit Switch | Stops crane movements at set points | Electronics | EN 60947 | 12 |

| Brakes | Halts crane movement to prevent accidents | Metal | ISO 25649 | 6 |

When evaluating tower crane hoists, it's crucial to understand the various types and the performance metrics that determine their effectiveness on the job site. Tower crane hoists are categorized primarily into hydraulic and electric types, each offering distinct advantages. Hydraulic hoists are often favored for their smooth operation and ability to handle heavy loads with precision. In contrast, electric hoists are known for their speed and efficiency, making them ideal for projects requiring rapid lifting capabilities.

Performance metrics play a vital role in selecting the right crane hoist. Key indicators include lifting capacity, speed of operation, durability, and maintenance requirements. A hoist's lifting capacity must align with the specific needs of the project while ensuring safety standards are met. Additionally, as the crane and hoist market is projected to grow significantly, with a forecast increase from USD 32.85 billion in 2024 to USD 34.68 billion in 2025, understanding these performance factors becomes essential for contractors aiming to invest in suitable equipment for optimal performance. As the market evolves, keeping an eye on advancements in hoist technology will also be critical for maximizing efficiency and safety on construction sites.

The jibs of a tower crane play a crucial role in determining its efficiency and performance on construction sites. These horizontal structures extend outward from the tower and significantly influence the crane’s load distribution and reach. A well-optimized jib design allows for better weight distribution, minimizing stress on the crane's structure and ensuring stability during operations. By optimizing the length and angle of the jib, operators can maximize the crane's capability to lift and maneuver loads, making it an essential component in any tower crane setup.

Moreover, the optimization of tower crane jibs directly impacts the operational radius of the crane. A longer jib can extend the reach of the crane, enabling it to access different areas of the construction site without the need for repositioning the entire crane. This not only enhances productivity but also reduces the time taken to complete tasks. Additionally, varying the configuration of the jib can help mitigate potential obstructions on site, ensuring that materials are delivered exactly where they are needed. Understanding the importance of jibs thus ensures that construction projects run smoothly and efficiently.

The gearbox is one of the most critical components of a tower crane, playing a pivotal role in the transmission of power from the motor to the crane's mechanisms. According to the International Journal of Engineering Research, approximately 30% of crane operational downtime is attributed to gearbox failures. To ensure longevity and reliability, regular maintenance routines are essential. This includes frequent oil changes, typically every 1,000 hours of operation, and monitoring for unusual vibrations or sounds that may indicate wear or malfunction.

Moreover, performing regular inspections can significantly extend the lifespan of gearbox components. The Society of Manufacturing Engineers suggests utilizing advanced diagnostic tools to measure the wear and tear on gear teeth and assess lubrication effectiveness. Implementing a predictive maintenance strategy not only reduces the chance of unexpected breakdowns but also enables operators to plan for repairs efficiently, minimizing operational disruptions. Keeping these maintenance practices in mind can maximize the performance and reliability of tower cranes and their gearboxes, ensuring they meet the demands of modern construction projects.