Understanding Tower Crane Parts is essential for any construction project. According to a report by Freedonia Group, the demand for cranes, including tower cranes, is expected to grow significantly. The global market for construction cranes is projected to reach $16 billion by 2024. This growth highlights the importance of knowing the functionalities of different tower crane parts.

Tower cranes play a vital role in modern construction. They lift heavy materials to great heights efficiently. However, not all tower crane parts are created equal. Each component, from the mast to the jib, fulfills a specific function. Improper knowledge of these parts can lead to accidents or inefficiencies. In 2019, OSHA reported that improper crane operation and maintenance contributed to over 60 fatalities in the construction sector.

Construction professionals should prioritize understanding these components. Regular inspections of tower crane parts are necessary to ensure safety and longevity. Many operators overlook crucial maintenance checks. This can be detrimental to both the project and worker safety. Being aware of the significance of these parts can prevent costly mistakes and enhance operational effectiveness. Knowledge truly is power in the world of construction.

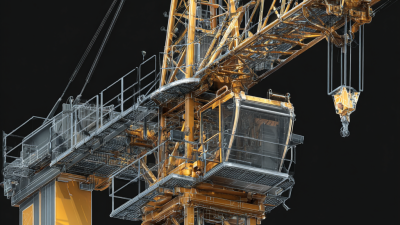

Understanding the Basics of Tower Crane Components involves knowing their essential parts. A tower crane typically features a base, mast, slewing unit, and jib. Each component plays a crucial role. For instance, the mast provides vertical support and stability. In 2021, a report by the International Cranes and Specialized Transport indicated that a well-maintained mast can enhance lifting efficiency by up to 30%.

The jib is another key component. It extends horizontally and carries the load. Proper positioning of the jib is vital. If it’s too high, it can cause imbalance. Safety is critical. A data point from the Bureau of Labor Statistics states that improper crane operation leads to over 40% of workplace accidents. Safety inspections should not be overlooked.

Moreover, the counterweights are often neglected. These balance the load on the jib. Without adequate counterweights, the crane risks tipping. Many operators fail to check these regularly. Regular maintenance can prevent disasters. The Tower Crane Safety Coalition emphasizes that routine checks can reduce accidents by 50%. Effective management of these components is essential for success in construction projects.

This chart represents the weight distribution of various essential tower crane parts. Understanding the weight of these components is crucial for effective loading and safety management on construction sites.

Tower cranes are critical in construction, and understanding their parts is essential. The tower crane's main components include the mast, jib, and counterweights. Each of these parts plays a vital role in lifting operations. According to industry reports, faulty components account for 40% of crane accidents. Therefore, knowing how these parts function can significantly improve safety and efficiency.

The mast provides stability and support. A well-structured mast can handle heavy loads and high lifting heights. The jib extends horizontally and carries the load. Its length often determines the crane's lifting capacity. In fact, some jibs can reach up to 70 meters, allowing vast coverage on a construction site. Counterweights, though often overlooked, balance the crane’s load. Without the right amount of counterweight, the risk of tipping increases significantly.

Regular inspections are necessary to ensure all components function well. Ignoring minor wear and tear can lead to major accidents. Research shows that up to 50% of crane incidents could have been avoided with better maintenance. A small crack or loose bolt could result in catastrophic failure. Therefore, understanding the key functions of these parts is not just beneficial; it’s critical for every construction project.

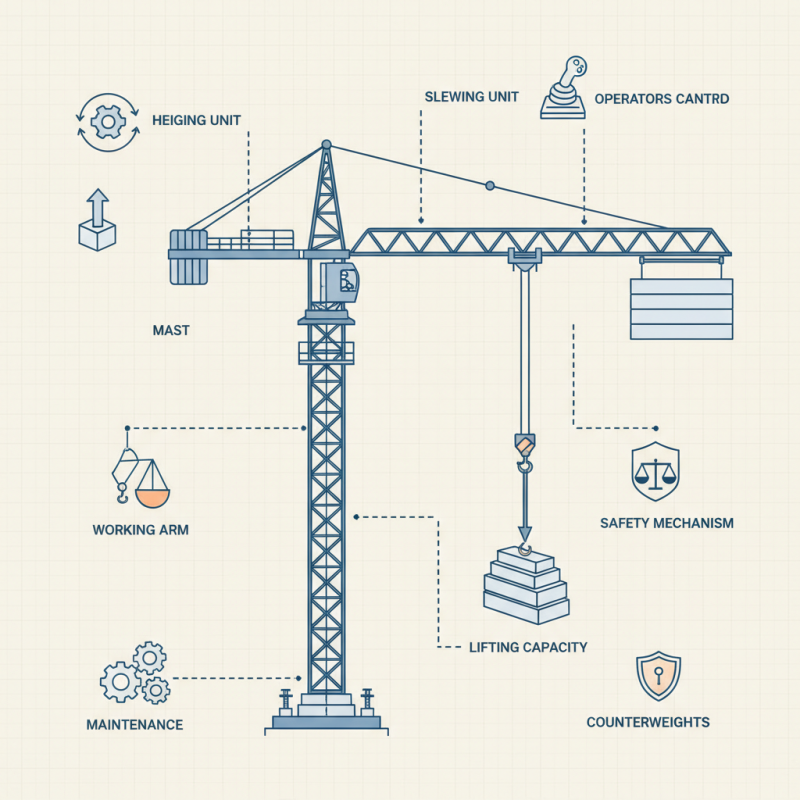

Tower cranes play a crucial role in construction. However, safety features are vital for preventing accidents. Operators must be aware of various safety mechanisms. For instance, overload sensors are essential. They prevent lifting loads beyond the crane's capacity. This feature helps avoid structural failures.

Another important aspect is the emergency shutdown system. In the event of an unforeseen issue, this system halts operations immediately. Operators should test these features regularly. Ignoring them can lead to disastrous outcomes. Additionally, proper training for personnel cannot be overlooked. Knowledge of safety protocols ensures that everyone on site remains vigilant.

Even with advanced technology, human error is a factor. Miscommunication can lead to serious accidents. It's critical to foster a culture of safety. Encourage all team members to speak up if something seems off. Regular safety meetings can also help. Reflecting on past incidents often reveals areas for improvement.

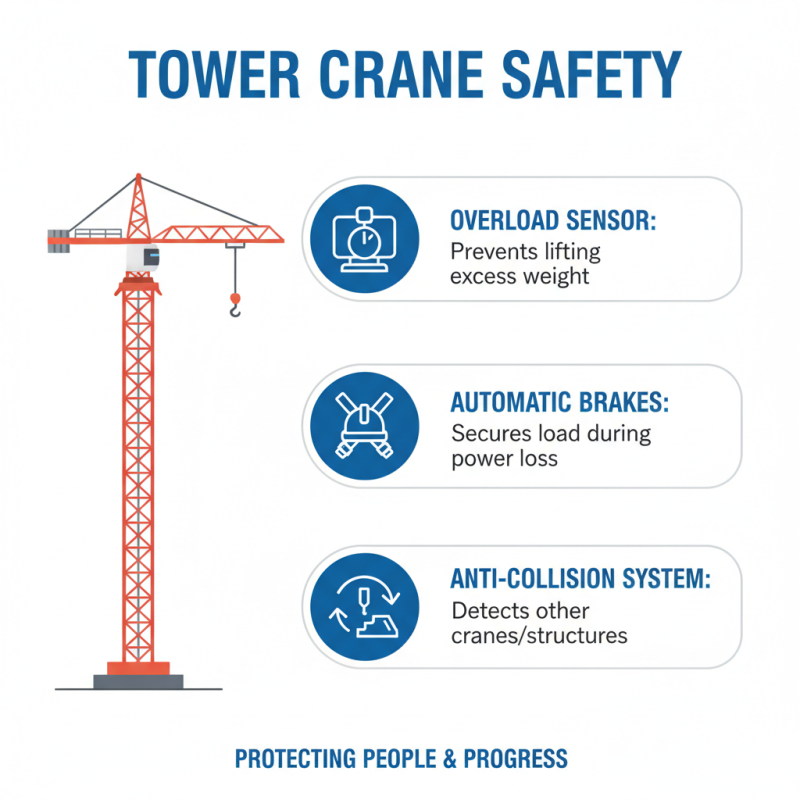

Regular maintenance of tower crane parts is crucial for safety and efficiency. Inspect the essential components frequently. This includes the hoist, cables, and brakes. Look for signs of wear and tear. A small issue can lead to major problems.

Pay attention to lubrication. Keep parts well-greased to prevent friction. This will enhance performance and extend lifespan. Proper storage also matters. Store parts in a dry, clean area to avoid corrosion.

Create a detailed log for all maintenance activities. This helps track recurring issues. Inconsistent maintenance can lead to costly repairs. Remember, proactive measures are better than reactive fixes. Always be vigilant and precise in your inspections.

| Part Name | Function | Maintenance Tips |

|---|---|---|

| Hoist Mechanism | Raises and lowers loads | Regularly lubricate gears and inspect for wear |

| Jib | Main horizontal part of the crane | Check for structural integrity and cracks |

| Counterweights | Balances the load being lifted | Ensure counterweights are secured and undamaged |

| Tower | Vertical structure that supports the crane | Inspect for corrosion and structural reliability |

| Slewing Ring | Allows horizontal rotation of the crane | Lubricate regularly and check for play or damage |

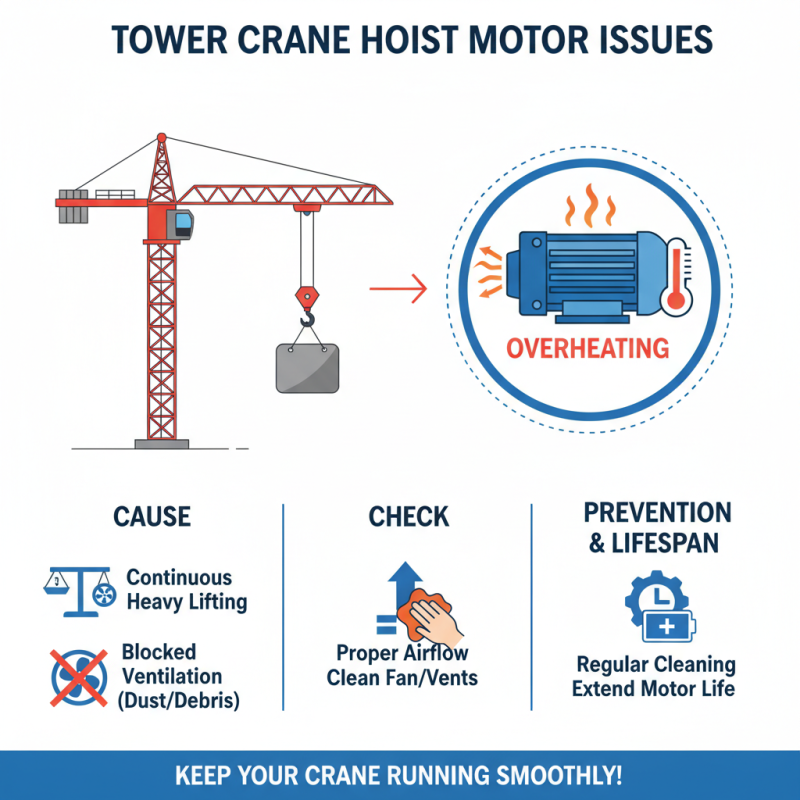

Tower cranes are essential in construction, but they can face various component issues. One common problem is with the hoist motor. It may overheat due to continuous heavy lifting. When this happens, operators should check for proper ventilation. Dust and debris can block airflow. Regular cleaning can prevent overheating and extend the motor’s lifespan.

Another frequent issue involves the wire ropes. They can wear out quickly under tension and stress. Regular inspections are vital here. Look for fraying and corrosion. If found, replace the ropes immediately. Delaying this can lead to serious safety risks. Operators often overlook this step. It's crucial to address it promptly.

Lastly, the slewing ring can develop play over time. This issue affects stability and movement accuracy. Operators should monitor for excessive slack during use. Tightening the bolts can temporarily fix the problem. However, if the play persists, replacement may be necessary. Ignoring this can lead to further complications. Understanding and addressing these issues is necessary for safe operations.