In the fast-paced world of construction, efficiency is paramount, and the role of tower cranes cannot be understated. With their towering presence at construction sites, these machines rely heavily on several essential components to ensure optimal performance. According to Dr. Emily Jensen, a noted expert in heavy machinery and tower crane operations, "The efficiency of any tower crane is intrinsically linked to the quality and functionality of its parts." This highlights the significance of understanding and investing in the right tower crane parts to enhance construction capabilities.

As we approach 2025, industry trends reveal a growing emphasis on the technological advancements of tower crane parts, which are crucial for meeting modern construction demands. Key components such as the hoist mechanism, jib, and control systems have evolved dramatically, contributing to increased safety and reduced operation times. By delving into the top five essential parts of tower cranes, construction professionals can gain insights into optimizing efficiency and ensuring smoother project execution. The selection of premium quality tower crane parts not only bolsters operational efficiency but also elevates overall safety on construction sites, paving the way for innovative building practices in the coming years.

When it comes to tower cranes, several key components work in harmony to ensure optimal construction efficiency. The first crucial part is the hoist mechanism. This system is responsible for lifting and lowering loads with precision, and its reliability directly impacts a project’s timeline and safety. A well-maintained hoist can significantly reduce downtime and enhance productivity on site.

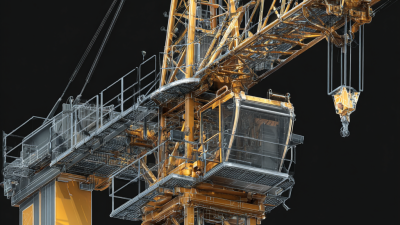

Another essential component is the tower structure itself. It provides stability and support to the entire crane, allowing it to reach impressive heights while maintaining safety standards. The design and materials used for the tower must withstand dynamic forces to ensure durability over the course of a project. Additionally, the slewing mechanism plays a vital role in allowing the crane to rotate and move loads horizontally, which is essential for efficient material handling in tight spaces.

Lastly, the electrical system must not be overlooked. This includes controls and safety systems that ensure seamless operation. An advanced electrical setup not only enhances functionality but also increases operator efficiency, reducing the likelihood of errors and accidents on the job site. Together, these components create a robust framework for tower cranes, making them indispensable in modern construction.

| Component | Function | Material | Maintenance Frequency | Average Lifespan |

|---|---|---|---|---|

| Rotating Jib | Supports and moves loads | High-strength Steel | Monthly | 15 years |

| Hoist Mechanism | Lifts and lowers loads | Aluminum Alloy | Bi-Monthly | 10 years |

| Counterweights | Stabilizes crane | Concrete | Annual | Indefinite |

| Rotation Mechanism | Enables crane to rotate | Steel Bearings | Quarterly | 12 years |

| Control Cabin | Controls crane operation | Fiberglass | Semi-Annual | 7 years |

The crane jib is a crucial component that directly influences a tower crane’s load capacity and reach. Designed to support the lifting mechanism, the jib's shape and length play pivotal roles in determining how much weight the crane can safely handle. A longer jib often allows for greater reach but can compromise stability and load capacity if not designed properly. Therefore, understanding the balance between reach and effective weight distribution is essential for optimizing construction operations.

Additionally, the materials used in jib construction significantly affect its performance. Advanced materials can provide a lighter yet stronger jib, enhancing overall efficiency. Engineers must consider factors such as wind resistance and potential flexing under load when designing the jib. Moreover, innovative jib designs incorporating telescopic elements or adjustable angles can improve versatility on construction sites, allowing cranes to navigate complex structural challenges while maintaining safe lifting capabilities. Overall, an effective crane jib design is vital for maximizing operational efficiency in construction projects, ensuring that safety and performance are never compromised.

In the ever-evolving construction industry, the adoption of cutting-edge hoisting mechanisms is paramount for enhancing loading precision and efficiency. According to a recent report by MarketsandMarkets, the global tower crane market is projected to reach USD 8.38 billion by 2025, driven largely by advancements in hoisting technology. The integration of innovative systems allows construction professionals to minimize material waste and improve safety protocols, especially in high-rise projects where precision is crucial.

Recent studies indicate that advanced hoisting mechanisms, such as wireless control systems and automatic load monitoring, can increase operational efficiency by up to 30%. These technologies not only enhance the accuracy of load placement but also reduce the time spent on lifting tasks, which can lead to shortened project timelines and lower labor costs. As tower cranes become increasingly equipped with such technologies, their role in optimizing construction processes continues to expand, ultimately contributing to the overall effectiveness and safety of construction operations.

In the rapidly evolving construction industry, the importance of safety features in tower cranes cannot be overstated. As the Tower Crane Rental Market is projected to grow to USD 22.1 billion by 2030, understanding key safety elements becomes critical for optimal construction efficiency. Among these, crucial safety features include load indicators, anti-collision systems, and emergency stop functions. These components play a vital role in preventing accidents and ensuring that cranes operate within their safe limits, significantly reducing the risk of workplace injuries.

Moreover, a robust supervision plan for crane operators is essential, particularly in regions such as British Columbia, where regulations mandate that every provisional crane operator must be supported by a written supervision plan. This plan is designed to enhance operational safety and efficiency, affirming that well-trained operators under supervision can effectively execute complex lifting tasks. Industry reports highlight that the tower crane market is set to experience substantial growth, with expectations of reaching USD 10.3 billion by 2035, driven by the increasing demand for advanced construction capabilities and safety compliance. The integration of these safety features and structured supervision will be pivotal for harnessing this anticipated market growth effectively.

Advancements in tower crane controls are revolutionizing the construction industry, enhancing operator efficiency and safety. Traditional crane operations often required workers to scale significant heights, exposing them to potential hazards and physical strain. However, innovations such as AI-enabled cranes are transforming this dynamic. These advanced systems allow operators to control cranes from the ground, significantly reducing the risks associated with high-altitude work. Such technologies not only keep operators safe and cool on the ground but also drive productivity through increased precision and automation in crane operations.

Advancements in tower crane controls are revolutionizing the construction industry, enhancing operator efficiency and safety. Traditional crane operations often required workers to scale significant heights, exposing them to potential hazards and physical strain. However, innovations such as AI-enabled cranes are transforming this dynamic. These advanced systems allow operators to control cranes from the ground, significantly reducing the risks associated with high-altitude work. Such technologies not only keep operators safe and cool on the ground but also drive productivity through increased precision and automation in crane operations.

Moreover, the integration of artificial intelligence into crane controls is paving the way for smarter construction practices. Institutions like Nankai University's College of Artificial Intelligence are at the forefront of developing AI-driven solutions that optimize crane functionalities. By leveraging machine learning and data analytics, these systems can predict and adapt to various site conditions, enhancing operational efficiency. Consequently, the use of AI in tower crane controls is setting a new standard in the industry, allowing for faster project completions and improved resource management, thus reshaping the future of construction work.