In the ever-evolving landscape of the construction industry, understanding the intricacies of Tower Crane Parts has become vital for professionals looking to ensure efficiency and safety on job sites. As Mark Henderson, a renowned expert in construction machinery, aptly puts it, "The success of any project heavily relies on the reliability and functionality of its tower crane components." With this in mind, having a comprehensive guide to the essential parts of tower cranes can significantly enhance the decision-making process for construction managers and engineers.

As projects grow in complexity and scale, the demand for robust and efficient Tower Crane Parts continues to rise. This guide aims to provide valuable insights into the critical components that make up a tower crane, including hooks, winches, and lifting mechanisms, among others. By familiarizing themselves with these parts, construction professionals can not only streamline operations but also extend the lifespan of their equipment, ultimately contributing to the overall success of their endeavors in the field. Embracing this knowledge will empower teams to make informed choices and prioritize safety and productivity at every stage of the construction process.

Tower cranes play a crucial role in modern construction projects, characterized by their ability to lift heavy loads high above the ground. Understanding the key components of these cranes is essential for professionals in the industry. According to a report by ResearchAndMarkets, the global tower crane market is projected to grow at a CAGR of 6.5% from 2020 to 2025, which underlines the importance of efficient and reliable crane parts in meeting increasing construction demands.

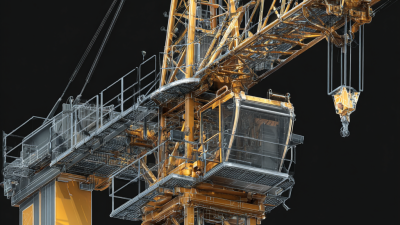

The primary components of a tower crane include the base, tower, jib, and the counterweights. The base anchors the crane to the ground and must be designed to withstand substantial loads. The tower provides the vertical reach, with sections that can be added or removed to adjust height. The jib is the horizontal arm from which loads are lifted, and the length of the jib affects the crane’s lateral reach and lifting capacity. Counterweights are essential for maintaining stability, and their design and placement are critical for safe operations. According to the European Federation of Construction Equipment (CECE), safety features in crane design, such as overload sensors and emergency stop controls, are vital to reduce the risk of accidents at construction sites.

In addition to the standard components, advancements in technology have led to the integration of smart systems into tower cranes. These systems can monitor performance and predict maintenance needs, thus enhancing operational efficiency and safety. A study by the International Journal of Construction Management highlighted that the use of advanced components could reduce machine downtime by up to 30%. As construction projects become more complex, the demand for reliable and innovative tower crane parts will continue to grow, driving the industry toward greater efficiency and safety.

Tower cranes are essential tools in construction, designed to lift heavy materials with precision and efficiency. Understanding the functions and importance of each tower crane part can significantly enhance a construction professional's ability to coordinate operations and ensure safety on site. Key components include the mast, which provides stability and height; the jib, which extends out to reach materials; and the counterjib, which balances the load. Each part works in tandem to enable the crane to perform its lifting tasks effectively.

The hoist mechanism is another crucial component, allowing for the vertical movement of loads. It typically consists of a motor, a winch, and a drum, functioning to raise and lower materials safely. Additionally, the steering control system is vital for maneuverability, enabling operators to position the crane accurately as required. Understanding the technical specifications and operational roles of these parts helps construction professionals make informed decisions about crane use, maintenance, and safety protocols, ultimately contributing to more efficient project execution.

Regular maintenance and adherence to safety procedures for tower crane parts are critical in ensuring optimal operation and longevity of equipment on construction sites. According to the International Organization for Standardization (ISO), approximately 25% of all construction accidents are related to cranes, with tower cranes being a significant contributor. This highlights the necessity of implementing rigorous maintenance schedules. Components such as the hoist mechanism, slewing rings, and electrical systems require periodic inspections and servicing. Preventive maintenance practices can reduce downtime by up to 30%, according to industry reports, which emphasizes the financial and operational benefits of a proactive maintenance approach.

The safety of tower crane components is another vital aspect for construction professionals. The Occupational Safety and Health Administration (OSHA) outlines specific safety protocols regarding the operation and maintenance of tower cranes. For instance, regular checks of safety devices and load-limiting systems are essential to prevent accidents due to equipment failure. Furthermore, data from the Crane Safety Institute suggests that improper maintenance procedures contribute to nearly 40% of crane-related incidents. Training periods for operators and maintenance personnel on safety standards and operational procedures can lead to significant reductions in incidents and enhance the overall safety culture on job sites. Implementing comprehensive safety and maintenance procedures will not only lead to compliance with regulations but also ensure a safer working environment for all staff involved in construction.

Selecting the right tower crane parts is crucial for ensuring the efficiency and safety of construction projects. According to a recent industry report by the Construction Equipment Industry Association, nearly 40% of project delays are attributed to equipment failures, underscoring the need for proper part selection. When choosing parts for tower cranes, professionals must consider factors like load capacities, operating heights, and compatibility with existing machinery. It's vital to evaluate the application requirements meticulously, as the correct components can enhance performance and minimize downtime.

Furthermore, understanding the latest advancements in tower crane technology can significantly impact decision-making. The 2023 Global Crane Market Analysis reported that the demand for modular and customizable components has surged by 25% in the past two years, reflecting a shift towards more adaptable solutions in construction. Professionals should prioritize parts that not only meet current project needs but also allow for future scalability. Additionally, leveraging data analytics can provide insights into part performance trends, assisting in making informed choices that align with project timelines and budgets.

| Part Name | Material | Weight (kg) | Load Capacity (tons) | Application |

|---|---|---|---|---|

| Slewing Mechanism | Steel | 350 | 5 | Rotation control |

| Luffing Jib | Aluminum | 250 | 8 | Height adjustment |

| Hoist Rope | Synthetic Fiber | 50 | 10 | Load lifting |

| Operator Cabin | Glass/Steel | 200 | N/A | Operator control |

| Counterweight | Iron | 400 | N/A | Stabilization |

As we look towards 2025, the evolution of tower crane technology is poised to redefine construction methodologies. Industry reports predict a heightened emphasis on automation and connectivity, with 70% of construction professionals recognizing the potential of Internet of Things (IoT) integration. These advancements will facilitate real-time monitoring of crane performance and location, enhancing efficiency and safety on job sites. The integration of sensors and AI algorithms within crane components is expected to reduce human error and optimize operational workflows, which is crucial as construction demands rise.

Moreover, sustainability is emerging as a pivotal trend driving the development of tower crane parts. Recent studies indicate that nearly 80% of construction firms are seeking eco-friendly solutions to minimize their carbon footprint. Innovations in materials and energy-efficient designs are expected to gain traction, allowing cranes to operate with lower energy consumption. This transition will not only meet regulatory pressures for greener construction practices but also align with broader industry goals of sustainable building.

With these trends shaping the future landscape, construction professionals must stay informed about the evolving technologies and components that will enhance both performance and environmental responsibility in their projects.